Kesteven & Sleaford High School: Live Case Study

Kesteven & Sleaford High School is refurbishing a Food Technology room into a multi-purpose facility for the 21st Century.

Innova's Installation team are currently on site and after two weeks, the new room is definitely taking shape. The selective academy, constantly strives to give young people the very best educational experience and the opportunity to pursue their chosen career. As the new Food Preparation and Nutrition GCSE syllabus is popular with Key Stage 4 students at the school and to inspire pupils at all levels, Kesteven and Sleaford High planned to refurbish their Food Technology room into a multi-purpose facility catering to their needs.

Securing funding for the refurbishment

Following a bid application orchestrated by Head of Technology Julie Pankhurst and Operations Manager Andy Allen, the school was successful in obtaining the majority of the money needed from The Savoy Educational Trust for the refurbishment of their facility.

Josephine Smith, Head of School said: “My thanks go to The Savoy Education Trust for their significant contribution to improving facilities for students at the High School.

“This refurbishment will benefit every Key Stage 3 student as they study Food Technology, inspire our GCSE option students and provide a great venue for some of our most popular extra curricular clubs too.”

Developing the design

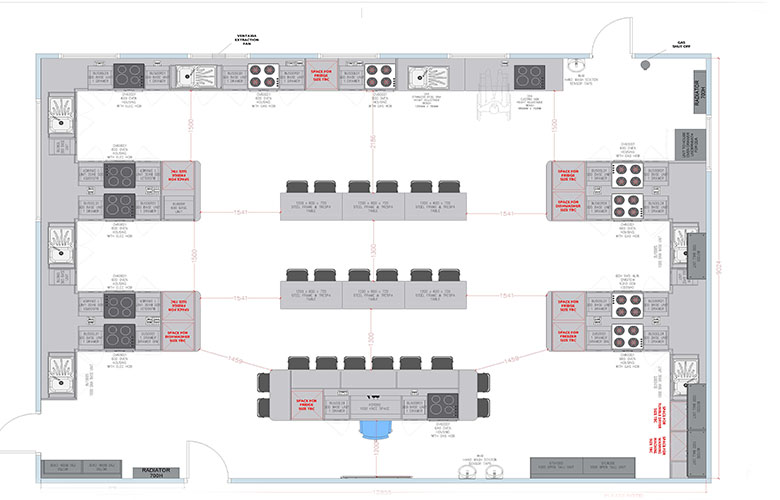

The initial brief to Innova, was to create a stimulating and modern high end Food technology room maximising space, with practical cooking areas, a teacher demonstration zone as well as a section for theory and written work, meeting regulatory requirements.

Innova’s experienced designer created a number of proposals taking all the key factors into consideration including health and safety, disability access as well as building lockable storage units around the room to house equipment and ingredients.

The final design is a bay layout providing “discrete kitchen area” around the perimeter with a central zone for theory lessons. The new teacher demo area presents the perfect platform to capture student’s interest.

With the plan finalised and quoted, Innova secured the turnkey contract, based on design and value for money.

The planning phase

One of the most important elements of any construction project is the six weeks leading to the first day onsite – the planning phase!

During this period, the Innova team carried out a number of tasks including scheduling of key dates, site specific resource planning plus introductions, design review and updates. A detailed onsite survey was conducted to plan entry and egress routes, check the main service locations, plan the service supply and capacity as well as carry out a health and safety assessment. Once the survey was completed the construction phase plan, site specific RAMS and the On-Site Health and Safety documents were prepared.

Laying the foundation

Having completed the planning stage we now move onto site to lay the foundations and install the ceiling and lighting

The first few days of the project on site are hectic and changes can occur – the time when a fully furnished space becomes a building site! Our site team now gets stuck in with a full rip out of the old room step by step:

Check all existing services for loading pressures and isolate existing valves and electrical boards as well as all the services within the room.

Rip out all existing fitted furniture and dispose into the skip. Remove existing flooring, suspended ceiling and grid plus existing lighting and skip accordingly.

Any redundant cabling and piping is removed and isolated in accordance with regulations.

First Fix, gas, water and electrics – Mark out using M&E drawings the new positions for gas, water and electric, create floor trenches using a petrol powered grinder with a diamond tip blade. Install pipework and cabling into separate trenches as per the drawing then fill with concrete, level and leave to dry.

New suspended ceiling 25mm white powder coated grid suspended on galvanised wire supports installed. Fitted with 600 x 600 mm white Armstrong tiles.

24 No LED lighting units, including emergency lighting, fitted to the ceiling grid, and all new cabling linked back to the residual-current device (RCD) board in the room. New 8 way 3 phase fuse board with safety cut off installed.